This application note describes the proper way to manage the heat produced by the UltraBright family of products. By following these recommendations you will be able to achieve continuous operation of the X-ray source. It is important to provide proper thermal management for the source. Different applications and system configurations of this device will require different thermal management strategies. In this application note you will find some examples of heat sinks that we use in our factory to thermally manage the unit. The goal is to keep the anode at a temperature of less than 70 °C while the unit is running at full power. For a unit with a Tungsten target, the maximum heat produced at the anode is 80 Watts, while for a unit with a Copper or Molybdenum target, the maximum heat produced at the anode is 60 Watts maximum.

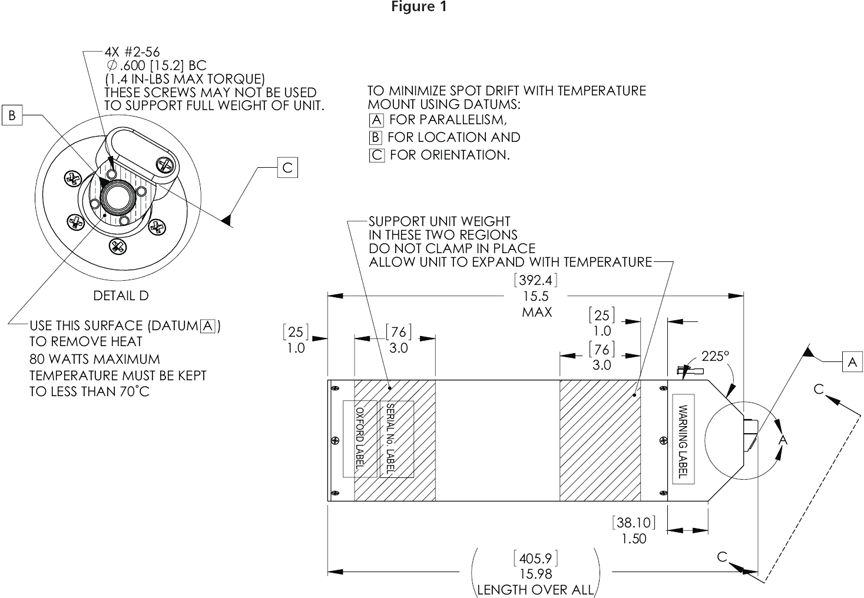

Figure 1 shows a portion of outline Drawing Number 8236. In the lower right corner of the drawing there is a view which indicates the surface that should be used to remove heat from the unit. Some heat also travels up the side of the conical cover but air blowing on this conical surface alone is not sufficient to cool the unit adequately. A heat sink must be attached to the surface indicated. The style of the heat sink is up to the user and will depend upon the location of other devices or mechanisms used in conjunction with this X-ray source.

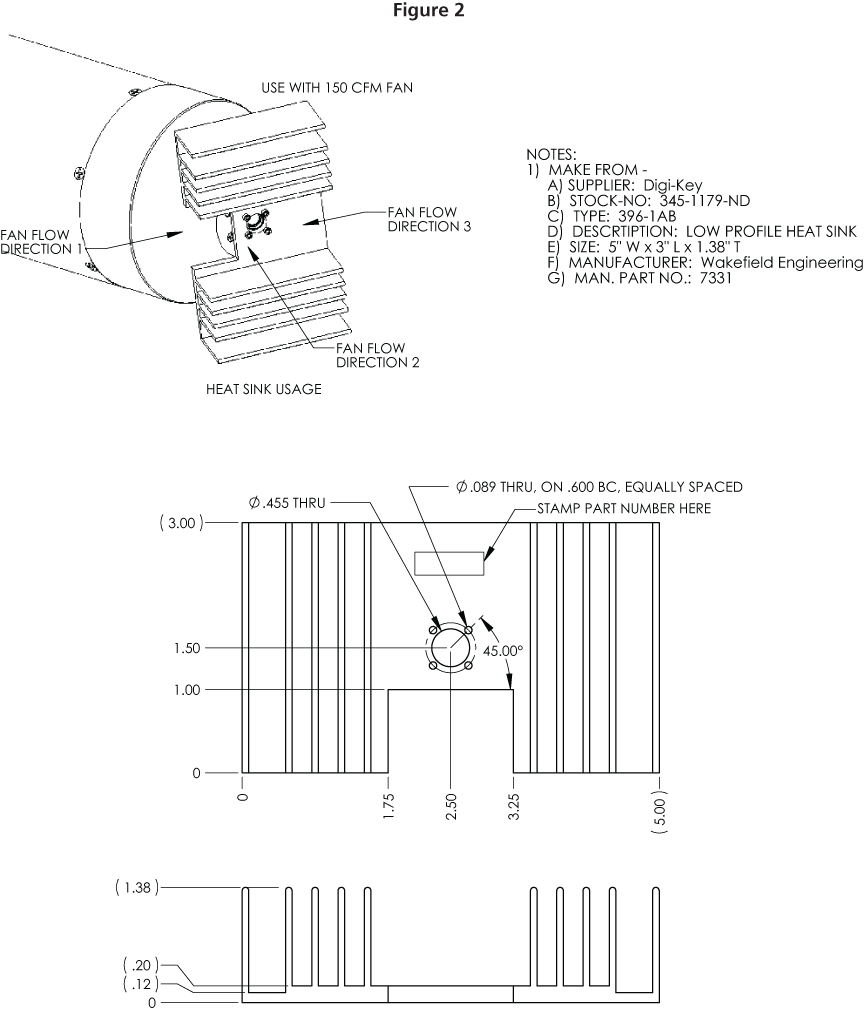

Figure 2 is drawing number 9474 which shows an inexpensive heat sink solution which will work well with a 150 CFM fan if the fan is blowing directly on the finned region. This solution is not ideal for applications which require close access to the exit window. In addition this is not intended to hold the source in relation to other devices to prevent spot drift due to thermal expansion of the unit.

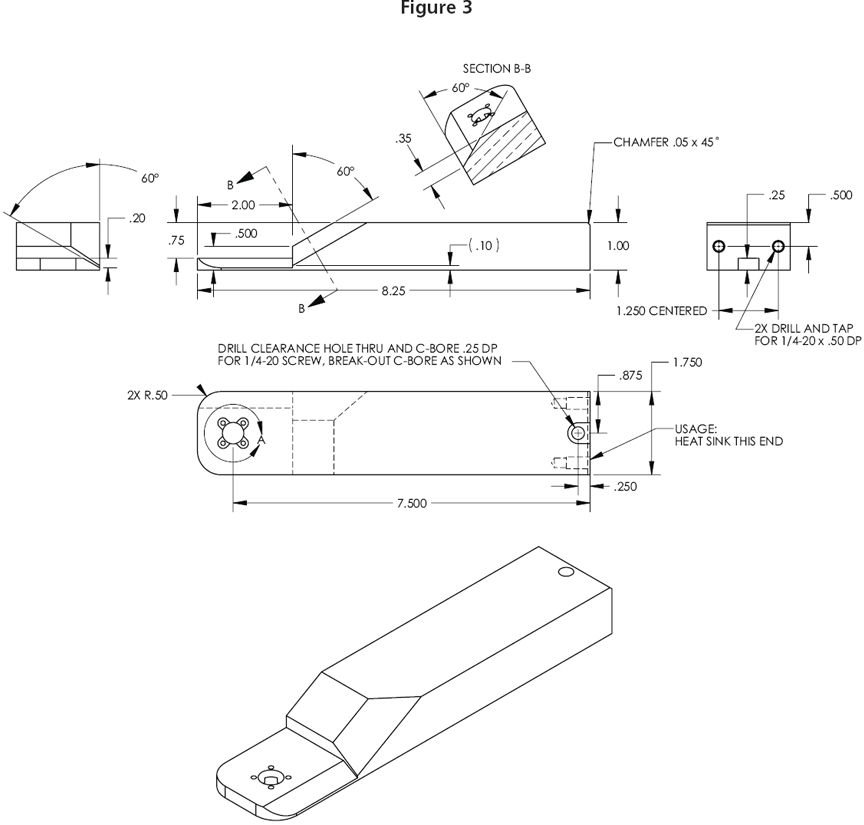

Figure 3 is drawing number 9506 and shows the heat sink we use during spot photo measurements of the X-ray spot size. The bar is hard mounted to a base which is fastened to an optical table. This bar then provides a fixed datum plane for subsequent measurements. A 150 CFM fan blows continuously on this bar and the front of the unit. To allow for thermal expansion of the unit, the rest of the source rests on two plastic cradles which are NOT clamped to the unit but still support a majority of the weight of the unit.

UltraBright has a thermal switch that is connected to an interlock. The maximum operating temperature of the anode is 70 °C. The thermal switch will automatically shut down the source if the temperature of the anode exceeds 70 °C and FAULT TUBE OT will be displayed on the LCD of the controller. It is important for you know when the unit is over temperature so that you can take actions to properly cool the unit. The thermal switch adds an additional level of protection to the cooling system safeguards.

Oxford Instrument X-ray Technology Technical Support would be pleased to review any mounting configuration and thermal management system the user has designed and make recommendations.